1 August 2022

Offshore floating wind… Are we prepared for it?

by Szen Ong

Mention renewable offshore wind turbines and most people imagine rigid wind turbines set against an ocean horizon. However, the arrival of floating offshore wind turbines is beginning to change mindsets. It also promises bigger business opportunities for offshore wind developers, renewable energy operators and many other businesses involved in this fast-growing sector.

When contemplating this evolution of the offshore wind sector, key questions arise;

- How do offshore floating wind turbines compare to the traditional fixed offshore wind turbines?

- Will failures already seen in fixed offshore wind turbines be replicated in newer floating configurations?

- What other challenges do floating designs pose?

- Are we able to conquer these challenges and at what cost?

Floating units

The key differentiating feature of floating offshore wind turbine systems is that the turbine towers are not anchored directly onto the seabed via monopiles, jackets or gravity bases. Instead, they sit on top of a buoyant floating unit such as a barge, spar, semi-submersible or tension-leg platform

(TLP). Such assets present a number of different issues.

Risk of multiple failure

These floating units are anchored to the seabed with mooring chains or tension lines similar to those used in floating offshore oil and gas platforms and semi-subs. Mooring systems are safety-critical in any floating offshore structure and failure usually has catastrophic results.

However, unlike typical single floating oil and gas platforms, offshore floating wind developments consist of clusters of floating wind turbine units in relatively close proximity to one another. Depending on the types of turbine and mooring configurations used (eg a daisy-chain configuration), any failure in the moorings on one unit within the cluster could impact the integrity of multiple neighbouring floating units.

Mooring complexity

Secondly, with the exception of TLPs, most floating designs rely on a standard spread mooring system. Whilst the moorings of an individual unit can take up a large subsea footprint, the moorings of multiple floating units within a cluster development can often create complicated and congested subsea mooring patterns. Adding to the subsea congestion are the valuable infield array cables linking each of the floating wind turbines to the substations.

There is an ever-growing desire by manufacturers and developers to increase power generation capacity per unit by developing larger wind turbines. This poses a major challenge when it comes to designing bigger floating offshore wind turbines, because the larger the unit, the higher its centre of gravity. Overcoming this instability usually requires the addition of extra mooring lines or larger chains to the unit design. For multi-unit farms of larger floating wind turbines, this can result in very complicated arrays of subsea moorings.

In the case of shallow water fixed wind turbines, the subsea infield cables are laid and buried along the seabed between each turbine, with only a short section exposed to dynamic motion. However, adjacent floating wind turbines are connected by subsea cables which float at mid-water depth. Alternatively, if far enough apart, neighbouring floating units are connected by dynamic sections of cable which each join a static length of cable running along the seabed. In either example, these subsea cables need to be designed for full dynamic service along their entire length. This increases design complexity and, if incorrectly executed, can easily lead to reduced lifespan.

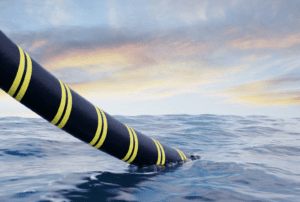

Subsea cables

Floating subsea cables have to be installed and operated between the mooring lines which anchor the floating units to the seabed. In this congested space, the potential for clashing issues between subsea cables and mooring lines is significantly increased during installation. Furthermore, if mooring line failures lead to floating units moving from their designated positions, multiple subsea cables could be impacted.

Compared to shallow water static cables, floating subsea cables are required to take on much more arduous service. Cable designs must incorporate additional anti-wear

layers, along with special material grades in the cable core components to increase fatigue resistance. All this increases the cable weight, size and cost, and impacts both ease of installation and the specifications of installation vessels.

Policy implications

What does all these mean from an insurance coverage and policy wording viewpoint? Traditionally, WindCAR policy wordings have been used extensively for offshore wind coverage, but these are written with shallow water fixed units in mind.

How transferable are these to new floating wind turbine configurations? First, a whole new section on mooring systems and associated marine warranty survey would have to be included. Whilst there is plenty of experience and know-how within the offshore upstream sectors to deal with this, care should be exercised as to how this is implemented. Multiple close-proximity units can have a major implication on EML considerations!

Careful attention will also be needed when considering damage versus defect implications in such floating wind turbine systems. How would the series loss clause be applied in a multiple-mooring failure scenario?

How would LEG2 or LEG3 impact coverage in these circumstances? As well as raising many new coverage considerations, this poses the question (from both insurer and insured’s standpoints) of how these policies would respond in such loss situations?

In closing

The rapid expansion of floating offshore wind developments and constant technological advancement in the ever-growing renewable wind sector are set to present us with more and more challenges. We can take comfort that many of these will be solved thanks to our experience and knowledge from the mature offshore oil and gas sector. However, to overcome the more taxing challenges posed by floating offshore wind turbines will require both fresh ideas and novel solutions.